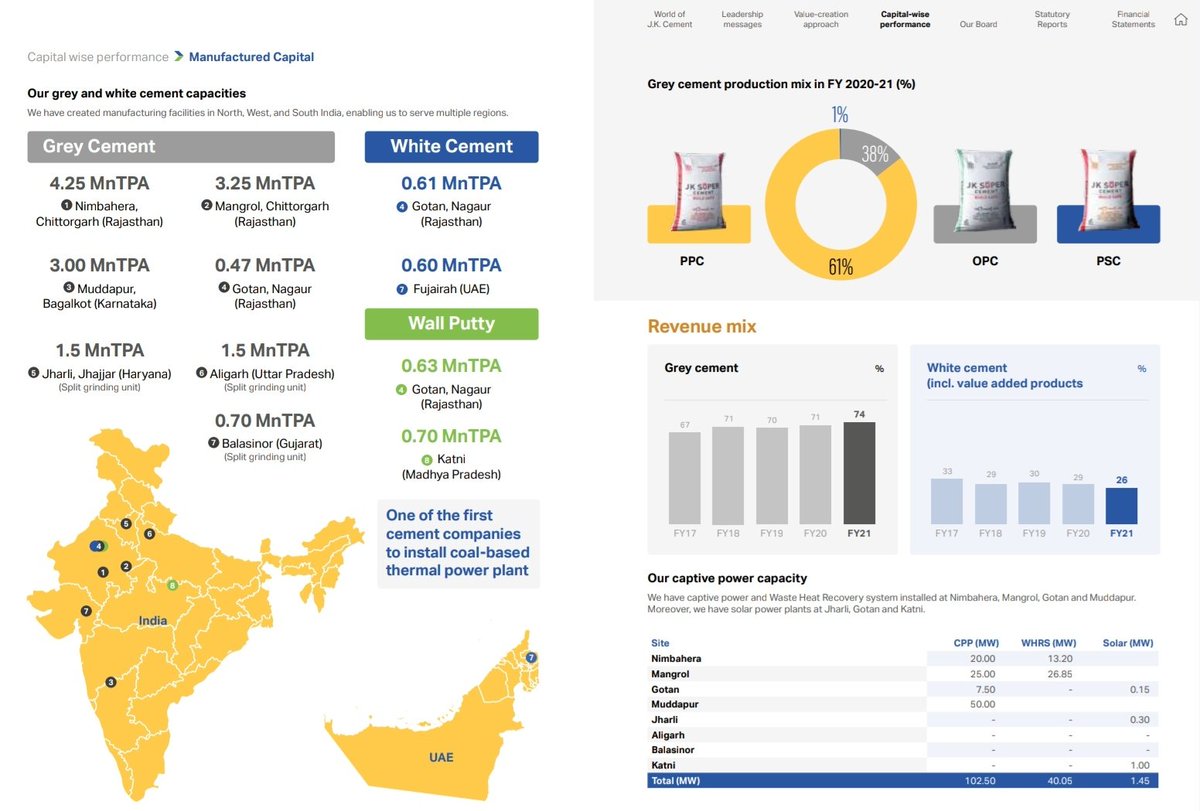

One of the fastest growing cement company JKCEMENT is expanding capacities by nearly 50% by FY24 & are also venturing into value added products such as Wood Amore and RepairMaxX.

JKCEMENT is also India's largest white cement and Wall Putty producer.

More from Saket Reddy

SAREGAMA

Today's closing is a monthly close and this is done & dusted, we now have a solid monthly close above the 10 year supply zone.

If the stock has broken out from a 10 year supply zone & a 20 year peak, surely something would've changed!

Do study the industry structure! https://t.co/zA3qztFzon

Today's closing is a monthly close and this is done & dusted, we now have a solid monthly close above the 10 year supply zone.

If the stock has broken out from a 10 year supply zone & a 20 year peak, surely something would've changed!

Do study the industry structure! https://t.co/zA3qztFzon

SAREGAMA at a very important juncture now on the monthly chart considering today's close is also a monthly close.

— Saket Reddy (@saketreddy) May 31, 2021

Nearing a breakout from over a 10 year supply zone! https://t.co/qpsSn3obrE pic.twitter.com/1xTmB6WvhK

ALKEM

Double Top Buy triggered above 3938.97 daily close on 1% Box Size chart. https://t.co/ZTxOtTreco

Double Top Buy triggered above 3938.97 daily close on 1% Box Size chart. https://t.co/ZTxOtTreco

ALKEM

— Saket Reddy (@saketreddy) January 8, 2021

The company is engaged in the development, manufacture and sale of pharmaceutical and nutraceutical products.

Double Top Buy above 3013 daily close on 3% box size chart, DTB active on 1% chart. pic.twitter.com/ToYx5T3Reb

You May Also Like

A brief analysis and comparison of the CSS for Twitter's PWA vs Twitter's legacy desktop website. The difference is dramatic and I'll touch on some reasons why.

Legacy site *downloads* ~630 KB CSS per theme and writing direction.

6,769 rules

9,252 selectors

16.7k declarations

3,370 unique declarations

44 media queries

36 unique colors

50 unique background colors

46 unique font sizes

39 unique z-indices

https://t.co/qyl4Bt1i5x

PWA *incrementally generates* ~30 KB CSS that handles all themes and writing directions.

735 rules

740 selectors

757 declarations

730 unique declarations

0 media queries

11 unique colors

32 unique background colors

15 unique font sizes

7 unique z-indices

https://t.co/w7oNG5KUkJ

The legacy site's CSS is what happens when hundreds of people directly write CSS over many years. Specificity wars, redundancy, a house of cards that can't be fixed. The result is extremely inefficient and error-prone styling that punishes users and developers.

The PWA's CSS is generated on-demand by a JS framework that manages styles and outputs "atomic CSS". The framework can enforce strict constraints and perform optimisations, which is why the CSS is so much smaller and safer. Style conflicts and unbounded CSS growth are avoided.

Legacy site *downloads* ~630 KB CSS per theme and writing direction.

6,769 rules

9,252 selectors

16.7k declarations

3,370 unique declarations

44 media queries

36 unique colors

50 unique background colors

46 unique font sizes

39 unique z-indices

https://t.co/qyl4Bt1i5x

PWA *incrementally generates* ~30 KB CSS that handles all themes and writing directions.

735 rules

740 selectors

757 declarations

730 unique declarations

0 media queries

11 unique colors

32 unique background colors

15 unique font sizes

7 unique z-indices

https://t.co/w7oNG5KUkJ

The legacy site's CSS is what happens when hundreds of people directly write CSS over many years. Specificity wars, redundancy, a house of cards that can't be fixed. The result is extremely inefficient and error-prone styling that punishes users and developers.

The PWA's CSS is generated on-demand by a JS framework that manages styles and outputs "atomic CSS". The framework can enforce strict constraints and perform optimisations, which is why the CSS is so much smaller and safer. Style conflicts and unbounded CSS growth are avoided.